In the recording studio, acoustic panels are a cornerstone of any good acoustic treatment plan.

While they may not absorb the low end as well as your bass traps, they do perform the entirely separate task of killing standing waves between parallel walls.

And it’s this issue specifically, that is especially problematic in the small cubical rooms of most home recording studios.

So to help you tackle this challenge, in this ultimate guide I’m going to teach you everything you know on this all-important topic.

First up…

Commercial Acoustic Panels vs Homemade DIY Panels

What you may not know is, building homemade DIY acoustic panels is actually a lot more common than you’d imagine.

It does require some trips to Home Depot, and basic carpentry skills, but it can potentially save you a lot of money.

Commercially bought acoustic panels however, while pricier, have the main advantage of being performance tested.

So you actually know for sure that they’re doing what they’re supposed to.

Many newbie studio owners make the common mistake of using materials such as carpeting, cardboard cup holders, or egg crate foam, which absorb the higher frequencies while allowing the low ones to remain.

And all this does is make the room sound dull and bassy.

So here’s what I’d recommend. If this is your first time around with this stuff, just buy them online.

And I recommend this route, mainly because you need to first get familiar with the “sound of a studio”.

Gain a few years of experience first, so you know what a good room should sound like, and what a bad room sounds like. THEN, if you want to later, experiment on your own with homemade panels.

So up next…

The 3 Key Features of Acoustic Panel Design

When you shop for acoustic foam online, there are 3 key features that you’ll have to consider.

First there’s the THICKNESS.

2″ is the industry standard. While 4″ is premium and more expensive.

Thicker is always technically better, but for their purposes, 2″ is good enough, and what I’d recommend. Later in this post I’ll show you a mounting trick to make them just as effective as the 4″ foam.

Next there’s the SURFACE PATTERN.

Panels typically have some type of 3D pattern on their outer surface. Wedged and Pyramid are the two most common.

These patterns do affect performance slightly, but the differences are minimal. So feel free to choose by aesthetics.

Next there’s the SQUARE FOOTAGE of the package.

The standard bundles normally come in packages of 6, 12, or 24. In sizes of 1ft², 2ft², or 2ft×4ft.

But the real number to pay attention to is the total square footage of coverage. A good starting point for most home studios is around 48ft².

This usually means:

- 48 – 1ft² panels

- 12 – 2ft² panels

- 6 – 2×4 ft panels

Any of these will work fine, but I’d generally recommend smaller panels because they are lighter and easier to mount with temporary adhesives that won’t damage your wall.

Up next…

NRC Ratings vs SRC Ratings: What’s the Difference?

Product descriptions typically include a “Noise Reduction Coefficient (NRC) rating” between 0 and 1.

The higher the number, the greater the absorption.

While this number may seem important, the truth is…it’s pretty much worthless for recording studios. And here’s why:

The test to determine this number only measures absorption at 4 frequencies:

- 2000 Hz

- 1000 Hz

- 500 Hz

- 250 Hz

Which means that no measurements are done below 250 Hz, where virtually all problematic frequencies in the studio exist.

That is why a different metric, known as Sound Absorption Coefficient (SRC), gives a much better representation of true performance.

Because this number measures absorption at a specific narrow band of frequencies. Unfortunately, it’s pretty uncommon these days to see SRC numbers actually posted.

Up next…

The 10 Best Acoustic Panel Packs on the Market Today

At this point, you’ve learned everything you need to know to choose a package that suits your room and budget.

And to save you a ton of painful research, I’ve already done all the heavy lifting for you…narrowing the options down to the 10 most popular and well-reviewed acoustic panel packs on the market today.

Each one is made by a top-name brand so there’s no question of what you’ll be getting.

For smaller rooms here’s what I recommend:

- Auralex DST 112 – (B&H)

- Auralex DST 114 – (Amazon)

- DMSKY Self-Adhesive – (Amazon)

- Fstop Wedge – (Amazon)

- Auralex Wedge 1ft² – (Amazon/B&H)

- Auralex Sonoflat 1ft² – (Amazon/B&H)

And for larger rooms, I’d recommend these instead:

- Auralex D36 Designer Series – (B&H/Thomann)

- Auralex 2ft² Pyramid – (Amazon/B&H)

- Auralex 2×4 Pyramid – (Amazon/B&H)

- Auralex Sonoflat 2ft² – (B&H)

Up next…

How to Build Homemade DIY Acoustic Panels

Maybe you already have some experience with commercial acoustic panels and you’d like to try something new.

Or maybe you’re just the handyman type and think it will be fun.

Or maybe you saw the prices in the previous section, and decided this is a better solution.

Regardless of your particular reason, you can easily build your own homemade panels with a little patience, and a few basic components.

So here are the tools you’ll need:

- Hammer/nails – to construct the frame

- Glue – to secure the insulation within the frame

- Staple gun/scissors – to secure and trim the outer fabric

- Mounting brackets – to mount the finished panel to the wall

Next, here are the materials you’ll need:

- Wood – to construct a standard-sized 2ft by 4ft frame.

- Fabric – to cover up the exposed insulation and give the finished panel a nice look.

- Owens Corning 703 – which is a special type of fiberglass that costs about 1/5th the price of acoustic foam and is just as effective

While the wood and fabric can be easily bought at any local home improvement store, Owens Corning 703 is not available everywhere, so you may have to order it online instead.

Once you’ve got everything you need, here’s a great video I found that walks you through the entire building process step-by-step:

Moving on…

How to Mount Acoustic Panels in the Corners of the Room

Once your acoustic panels are built (or arrive in the mail), it’s time to mount them in your room.

Assuming you already have bass traps, and have mounted them according to the recommendations in this post…

The next step is to make sure the area directly behind your studio monitors is covered, especially if those monitors have a rear-facing bass port.

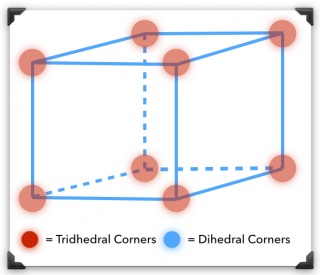

The third step is to cover the open dihedral corners (shown in the picture as blue lines) with acoustic panels.

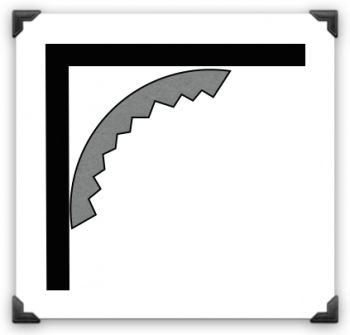

With commercial foam, fold your panels around the corner as shown below, remembering to leave an air gap for added low-end absorption.

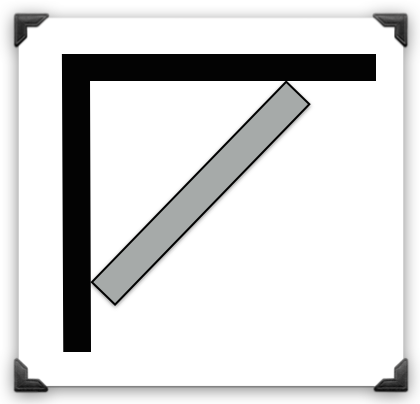

With homemade panels, position them diagonally across the corner like this:

Make sure you don’t use them all just yet though, because there’s still more area to cover on the walls.

Here’s how it’s done:

How to Position Acoustic Panels for Maximum Wall Coverage

Depending on the severity of a room’s acoustic problems…the ideal wall coverage could vary anywhere between 20-80%.

And the only way to know for sure, is to constantly re-test the acoustics after each new panel, using the clap test as described in this post.

It’s entirely possible that you may not even need every panel to reach the sound you’re after.

Because at a certain point, adding more panels than you need will only make the room sound uncomfortably dead.

In most cases though, home studios have fewer than the ideal number of panels. So to get maximum results from a shortage of panels, here’s what you do:

When covering an area of one wall, leave its reflection point open on the opposite wall…because one panel is sufficient to kill standing waves in that spot.

And if those instructions are too confusing, check out the diagram above, and it’ll be crystal-clear.

Up next..

How to Mount the Panels Without Ruining Your Wall

In home recording studios, where acoustic foam installations are unlikely to be permanent, there’s always the big worry of damaging your walls.

You also want to avoid damaging the acoustic foam itself, in case you ever want to take them down and sell them.

So the challenge here is to find an adhesive strong enough to support the weight of the foam, yet weak enough to be cleanly removed at any time..

Unfortunately, since every wall/paint job is different, there is no single solution that works in all cases. Which is why so many products exist to solve this one problem.

So up next…

3 Adhesive Strength Options for Mounting Your Acoustic Panels

Auralex more so than any other company, has developed a wide variety of adhesives to choose from for this one purpose.

Here are their 3 options:

- Auralex TubeTak Pro – (Amazon/B&H/Thomann)

- Auralex FoamTak – (Amazon/B&H)

- Auralex EZ-stick – (Amazon/B&H)

TubeTak is the strongest, but can be difficult to remove. EZ-stick is the weakest, but may not always hold well.

So FoamTak in my opinion, offers the best compromise between the two.

But the problem with FoamTak or any other spray-on adhesive, is that it leaves a big mess behind once everything is removed.

So here’s a trick I discovered in my own studio:

A DIY Hack I Discovered Through Years of Trial and Error

First, cover both the wall and the back of the foam with clear packaging tape.

Then spray the FoamTak or similar adhesive in between them.

With this method, you’ll be able to mount your panels while leaving ZERO adhesive residue on anything.

HOWEVER…If you try this idea, proceed at your own risk. Because like I said, every wall and every adhesive is different.

So test the tape on a small area of the wall first to make sure it can be removed later without damage.

And if all this stuff seems way too complicated, there’s one final option you can try which may be the best of all.

Rather than using an adhesive, you could instead try impaling clips, which screw into the wall, and are used to hang your acoustic foam by “impaling” them.

And that’s my final tip of the post.